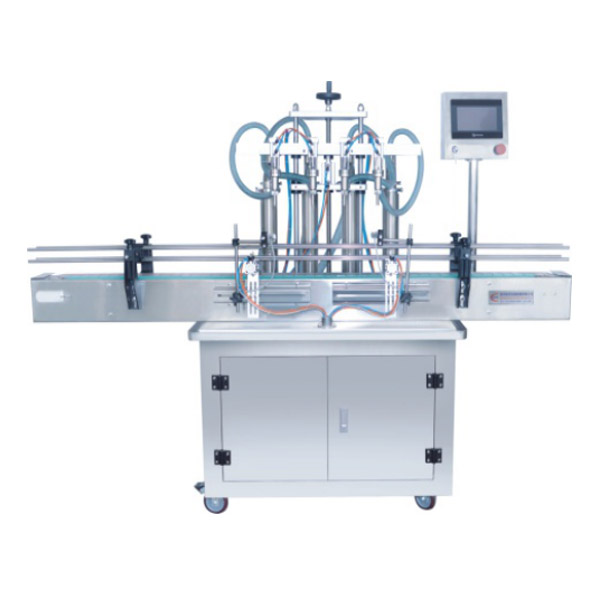

Product introduction:

Widely use for filling various kinds of liquid,paste,stickiness,sauce and paste with small grain.For example:beverage with fruit piece,honey,syrup,jam,peanut butter,sesame paste,tomato paste and chili paste,etc.This series is easy to be operation,clear,maintain and volume adjust,widely use for chemistry and oil filed. It can fill with different stickiness products.

Product features:

1.adopting PLC and touch screen control, has the advantages of accurate measurement, advanced structure, smooth operation.

2. Contact 2 the machine and materials are high quality stainless steel, beautiful appearance and no environmental pollution, simple assembly and disassembly, easy cleaning, according to the GMP standard.

3.the linear atmospheric pressure filling, through changing the filling time to realize the different measurement.

4.photoelectric sensors, proximity switches are used in advanced transmission sensory element, make sure no bottle filling, liquid level automatic control.

5.replacing bottles of different shapes, do not need to change parts, convenient adjustment, strong applicability;

6.the world-famous brands of electrical and pneumatic components, low failure rate, stable and reliable performance, long service life.

7. filling volume and filling speed adjustment is simple, the filling nozzle is provided with anti leakage device, ensure filling without drawing, no leakage.

2. Contact 2 the machine and materials are high quality stainless steel, beautiful appearance and no environmental pollution, simple assembly and disassembly, easy cleaning, according to the GMP standard.

3.the linear atmospheric pressure filling, through changing the filling time to realize the different measurement.

4.photoelectric sensors, proximity switches are used in advanced transmission sensory element, make sure no bottle filling, liquid level automatic control.

5.replacing bottles of different shapes, do not need to change parts, convenient adjustment, strong applicability;

6.the world-famous brands of electrical and pneumatic components, low failure rate, stable and reliable performance, long service life.

7. filling volume and filling speed adjustment is simple, the filling nozzle is provided with anti leakage device, ensure filling without drawing, no leakage.

Technical parameters:

|

Model |

HZGY500-4D |

|

Voltage |

AC220V,50/60HZ |

|

Power |

0.15KW |

|

Optional Filling Volume |

30-100/30-300/50-500ML 100-1000/200-1500ML 300-2500/1000-5000ML |

|

Production Speed |

20-30PCS/MIN |

|

Air Pressure |

0.4-0.6MPA |

|

Machine Size |

2000(L)×1050(W)×1650(H)MM |

Sample display:

SHARE:

PRODUCTS

- Vacuum packing machine

- Liquid Packing Machine

- Powder Packing Machine

- Granule Packing Machine

- Blister packing machine

- Transparent film packaging machine

- Pillow packing machine

- cup filling and sealing machine

- bottle blowing machine

- Packing machine production line (bag feeding)

- Shrinking machine

- Filling machine

- Labeling machine

Chinese

Chinese