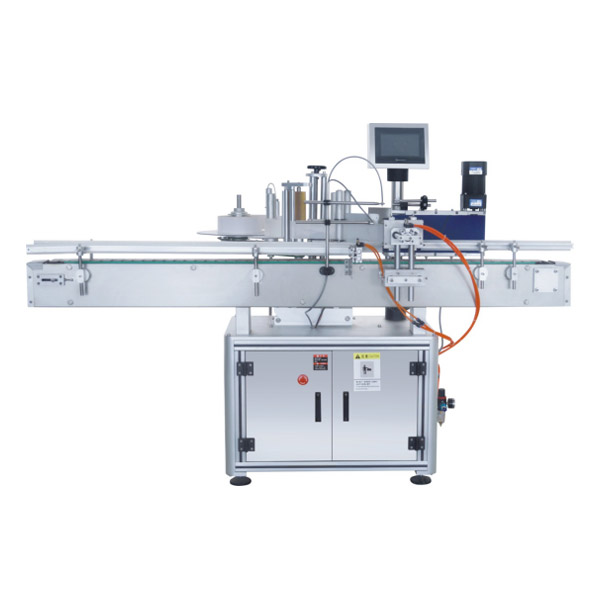

Product introduction:

Wide application range, can meet the needs of all round bottle labeling or semi-circle labeling, bottle labeling switching between simple, convenient adjustment; label overlap is high, with the standard bypass rectifying mechanism cannot take, standard deviation, labeling parts x/y/z three direction and inclination of eight degrees of freedom is adjustable, adjust the dead a high degree of coincidence, label; self-adhesive labels, adhesive film, electronic monitoring code, bar code etc.. Application Industry: widely used in food, medicine, cosmetics, daily chemical, electronics, hardware, plastics and other industries. Application example: PET round bottle labeling, plastic bottle labeling, canned food, etc..

Product features:

1.Labeling quality, using standard of spring cover belt, labeling smooth, no wrinkles, improve packaging quality;

2.Flexible application, bottle stand vertical labeling, with automatic sub bottle function, can be stand-alone production, can also be connected to the production line;

3. Intelligent control, automatic photoelectric tracking, with no matter no labeling, no standard automatic calibration and label automatic detection function, prevent leakage and label waste;

4. High stability, Matsushita PLC+ Matsushita touch screen + needle + German Matsushita Electric eye Leuze label consisting of senior electric eye control system, support equipment 7 x 24 hour operation;

5. Simple adjustment, labeling speed, conveying speed, bottle speed can be achieved stepless speed regulation, according to the need to adjust;

6.Durable, using three bar adjustment mechanism, make full use of triangular stability, solid durable machine. Made of stainless steel and advanced aluminum alloy, accord with GMP Production requirements.

2.Flexible application, bottle stand vertical labeling, with automatic sub bottle function, can be stand-alone production, can also be connected to the production line;

3. Intelligent control, automatic photoelectric tracking, with no matter no labeling, no standard automatic calibration and label automatic detection function, prevent leakage and label waste;

4. High stability, Matsushita PLC+ Matsushita touch screen + needle + German Matsushita Electric eye Leuze label consisting of senior electric eye control system, support equipment 7 x 24 hour operation;

5. Simple adjustment, labeling speed, conveying speed, bottle speed can be achieved stepless speed regulation, according to the need to adjust;

6.Durable, using three bar adjustment mechanism, make full use of triangular stability, solid durable machine. Made of stainless steel and advanced aluminum alloy, accord with GMP Production requirements.

Technical parameters:

|

Model |

TB-600 |

TB-600A |

|

Drive |

Step motor driven |

|

|

Direction |

Right/Left |

|

|

Labeling speed |

120-250PCS/MIN |

|

|

Label size |

W:10-80mm L:15-150mm |

W:10-150mm L:15-300mm |

|

precision |

+1mm(Subject to roundness and verticlity of the bottle) |

|

|

Label roll |

Max:∅300mm |

|

|

Label core |

Stander:∅75mm(3”) |

|

|

Machine size |

1600×800×1300mm |

1800×800×1300mm |

|

weight |

150kgs |

|

|

Voltage |

AC110/220V 50/60Hz 500W |

|

|

Coding device |

DT-280/DT-380 |

|

SHARE:

PRODUCTS

- Vacuum packing machine

- Liquid Packing Machine

- Powder Packing Machine

- Granule Packing Machine

- Blister packing machine

- Transparent film packaging machine

- Pillow packing machine

- cup filling and sealing machine

- bottle blowing machine

- Packing machine production line (bag feeding)

- Shrinking machine

- Filling machine

- Labeling machine

Chinese

Chinese